On the last lesson we met with a set of tools and equipment, necessary for practical work on sharpening the nail and hairdressing tools. Today we will learn how to handle tools for sharpening wizard, because many do not know how or do wrong( particularly the case of measuring instruments).

Let's start with a hammer. Молоток One of the main tools for sharpening wizard. As the shock bench tools, it presents a danger, if you use the wrong. Often newcomers hold a hammer in the wrong place, from here follow the trauma not only limbs, but other parts of the body.

Важно! Proper grip of the handle is a hammer at a distance 2/3 the length of the handle of the hammer.

В арсенале мастера желательно иметь два молотка: один легкий весом 200 гр другой- около 1000 гр.

With a pair of pliers, screwdrivers, pressures, Needle able to use almost all, because they had to work in the labor classes in school or at home, but how to deal with special tools sharpener for finishing manicure and hairdressing tools known to few. Diamond bar – important tool without which it is impossible to correctly perform the final stage of sharpening –finishing. It would seem that there is a complex – buy and sharpen. But when buying a diamond bar a few know, that it should be “open”т.е. so that it will work correctly you need to remove the top layer of small. For this purpose it is necessary to rub it thoroughly on a metal surface(better about iron) and after a while the bar surface is smooth and shiny yellowish. That bar can work. Pre-need to pick up for the finishing of the diamond block of the smallest grain 60/45(marking on the bar sometimes does not correspond to the real grain).

But when buying a diamond bar a few know, that it should be “open”т.е. so that it will work correctly you need to remove the top layer of small. For this purpose it is necessary to rub it thoroughly on a metal surface(better about iron) and after a while the bar surface is smooth and shiny yellowish. That bar can work. Pre-need to pick up for the finishing of the diamond block of the smallest grain 60/45(marking on the bar sometimes does not correspond to the real grain).

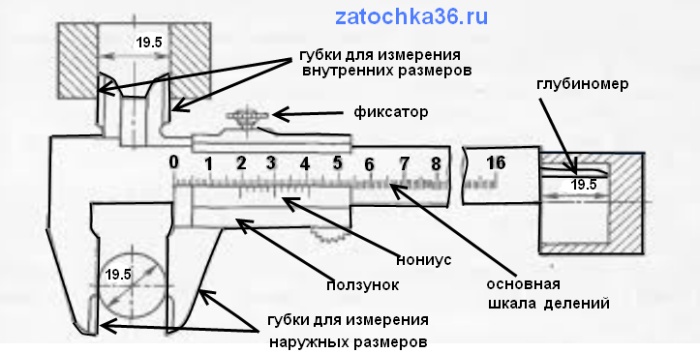

You also need to learn how to deal with an important tool for measuring the master –caliper, with whom the master will not leave even in a dream. Many are familiar with this tool from school, but not everyone knows how to use it. First of all you need to make sure the tool shelf. In the factory they give from time to time in the measurement laboratory to verify the accuracy,ru. And in the home is to verify that the zero millimeter scales and vernier surfaces,ru(на рис) and nineteenth bar graph surface exactly to coincide with the tenth stroke on vernier slider. There Calipers with micrometer dial, and electronic scoreboards. It is necessary to check the zero mark.

How to make measurement of caliper?

How to make measurement of caliper?

Calipers can be measured not only the external dimensions of the part, and inner( eg. diameter holes).

Measuring the outer size(for example, diameter of round parts).

1.Spreading thumb the tab located on the slider (movable part) tool

2.Grab detail lips putting a little effort.

3.Integer read on the millimeter scale, and the tenths and hundredths read on the exact coincidence mm and vernier scale. Например, на рис. visible, that whole millimeter scale 19 divisions, and on the vernier 5th division coincides exactly with the division on the main scale. It means. that the diameter of the circular parts is equal to 19 0.5 = 19.5 mm.

Likewise measured inside dimension, the only difference is that in the case come pointy sponge on the opposite side. These sponges can be used even as a compass.

Also some calipers feature depth gauge( protruding pin, Shear slider caliper).Depth is convenient to use in the measurement of the depth of blind holes, grooves, etc.. д.

depth measurement (for example, groove).

1.Spreading (we derive) the slider pin, sliding in a special trench in the tool body.

2.Drop(abut) Depth to the bottom of the slot and abut the end of the caliper on the workpiece surface (measurement start).

3. Read the testimony of the groove depth on the scale divisions, Similar measurements of length details.

When measured with high precision parts, apply micrometers. Its action is based on the movement of the screw along the axis during its rotation in the fixed nut. On the stem of a micrometer marked division, where a certain angle of rotation of the screw corresponds to a certain length. When clamping parts between the measuring planes must be issued ratchet clicks and then you can read the size on the length scale,ru.

Quite often the masters of the Exile have to measure the geometric angles on manicure and hairdressing tools. For this purpose there locksmith inclinometers. Uglomyer in its simplest form consists of two plates (rulers), enshrined together on the same axis, remaining movable on this axis (form a bevel), with scale, expressed in degrees. Scale can be ruled or line-circular, Allocated circumferentially around the axis, on one of the lines

For quality control of the work is often necessary to use optical tools such as magnifier and an optical microscope. Magnifier can have the usual form as a lens with the handle, and sometimes in the form of points. Typically, the final stage of treatment or nail cutters hairdressing tools I use a magnifying glass, because they can sometimes remain on the cutting edge of the blade is usually imperceptible eye mikrozausentsy or other unwanted particles. Sometimes there are situations, when you have to turn to an optical microscope, as an accurate picture of the blades of the contact zone can be seen under the microscope.

The work on sharpening masters often have to be used special tools, which can not be bought in stores. Many devices, for ease of operation and high-quality processing of nail, Hairdressing and other tools, I fashioned myself. How to deal with my devices and grinding equipment I teach at personal course in Voronezh.

The work on sharpening masters often have to be used special tools, which can not be bought in stores. Many devices, for ease of operation and high-quality processing of nail, Hairdressing and other tools, I fashioned myself. How to deal with my devices and grinding equipment I teach at personal course in Voronezh.